Before doing solder mask, make sure your finished PCB board is still in material

1. Get equipments from the cabinet. Here is a picture of equipments you will need:

You will also need ProMask Comp A and B from the freezer.

2. Mix ProMask Comp A and B together

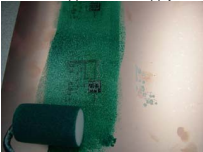

3. Use the roller to apply a thin layer on both sides of the PCB

4. Place the PCB into the oven underneath the LPKF ProtoMat S100. Set the temperature at 80 degrees Celsius (160 degrees farenheit) for 10 minutes

5. Let the PCB cool down for about 5 minutes

6. Print the PCB artworks onto transparency paper using our paper printer . Transparency paper is in the cabinet.

Click here for how to prepare transparentcy for solder mask

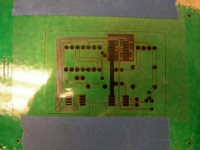

7. Match up the film to the pads of the PCB and secure the film with tape

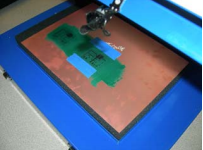

8. Place the PCB board on the UV exposure table

9. Expose each side of the PCB board for 60 seconds

10. Remove the transparency paper

11. Mix the developer with 1000mL of water (40 to 50 degrees Celsius)

Poor water into a tray

12. Brush away the solder mask from the PCB on both sides

13. Rinse the PCB

14. Place the PCB into the oven at 160 degrees Celsius (325 degrees farenheit) for 30 minutes

15. Wait for the PCB to cool down

Read more from LPKF tutorial: