Caution: In order to do this process, do not cut your pcb out of the board stock. Also, you’ll need your BoardMaster files.

1. Get the equipment you’ll need.

- Perforated acrylic board (in drawer of electronic bench)

- Felt (in drawer of electronic bench)

- Adhesive white tape (in storage cabinet)

- Squeegee (in storage cabinet)

- LPKF ProConduct (in refrigerator)

2. Warm ProConduct.

Take it out of the refrigerator and let it stay at room temperature for about 30 minutes. Or you can put it in a bowl of warm water for about 10 minutes.

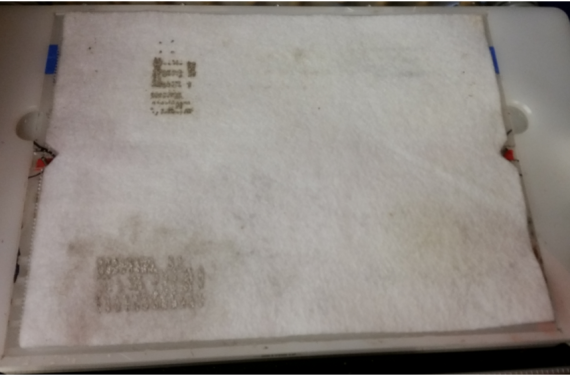

3. Apply adhesive white tape to both sides

Cut two pieces of the adhesive white tape, a little bigger than your pcb, and apply them smoothly to both sides. This will keep the ProConduct off the board, except where we drill holes in the next step.

4. Drill the holes

Open BoardMaster, selected drill plated, click All + and Start.

During this time, if you see “hole not found” message pop up, click yes.

5. Set up the vacuum table

Remove the white board from the LPKF vacuum table, by pulling straight up so that the pins stay in place. Put the perforated acrylic board in its place. Then lay down the felt on top of it.

6. Apply ProConduct

Put your pcb on top of the felt near the right or left side, where the vacuum is strongest. Turn on the vacuum with the switch on the white box under the LPKF. (The switch has three positions: left is auto; middle is off; right is on.) Use the squeegee to spread ProConduct over every hole in the board. You’ll see the vacuum pull the ProConduct into the holes.

Pick up the pcb and inspect the underside. Look into the holes to see if you can see the gray color of the ProConduct in every hole. If any hole is suspect, lay the pcb onto the felt with the underside uppermost and, with the vacuum running, spread the ProConduct.

7. Peel off the white adhesive tape

Slowly and carefully peel off the white adhesive tape.

8. Dry

Put the pcb in the oven under the LPKF for 30 minutes at 320 F.

9. Clean

Do this in the eye wash station only.

Remove the pcb from the oven and wait for 1 or 2 minutes so the pcb has cooled down. Get the spray bottle of cleaner under the LPKF. While holding the pcb under running water, spray it a few times with the cleaner.